Medbone® Biomaterials

We value high standards of quality!

Medbone® Biomaterials

Constant innovation is our Goal!

![bussiness-card-arsalan-[Recovered] bussiness-card-arsalan-[Recovered]](https://medbone.eu/wp-content/uploads/elementor/thumbs/bussiness-card-arsalan-Recovered-re3usuye8m4tghgjlc5yydm0c5kx2pn0wmlhpsde24.png)

Medbone® – Biomaterials

Innovating in Synthetic Bone Regeneration

Founded in 2008, Medbone® was established to address a critical gap in the field of synthetic bone graft manufacturing, providing healthcare professionals with reliable, high-quality biomaterials designed for predictable clinical outcomes.

Today, our products are distributed worldwide and used in more than 100 countries, across orthopedic, dental, and veterinary surgeries.

Driven by innovation and scientific excellence, we continuously strive to raise the standards of quality and performance of our products, ensuring that every solution meets the evolving demands of modern medicine. Our Research & Development department plays a key role in this process, driving technological advancement and safeguarding our intellectual property.

Biomaterials, engineering life.®

MEDBONE

Business Areas

Why Choose Medbone?

HIGH QUALITY Biomaterials

INNOVATIVE tools for healthcare professional

Products 100% RESORBABLE

High IMPROVEMENT of patients' quality of life

CLIENTS TESTIMONIALS

What They Are Saying

Medicabulum, Angra do Heroísmo.

“Having placed dental Implants since 1991 and only used synthetic materials for bone regeneration for the last 16 years and 5,000 grafts, I have worked with many synthetic biomaterials. The BTcp and HA materials manufactured by Medbone in Sintra, Portugal are simply the most effective I have experienced. When it came to working on the development of my own material, there was only one place to go, Medbone. The ceramic manufacturer who understands bone and healing.”

Scarsdale Dental , London.

“I have been an implantologist for 25 years and have always tried to use biomaterials to meet my needs. Almost 10 years ago I had my first contact with adbone®TCP and adbone®BCP and since then, given the excellent results achieved in biocompatibility, neovascularization, density and resorption of grafts, ease of handling and affordable cost, I started using Medbone’s products exclusively. I produced a work with histological comparative sections of Bio-Oss and adbone®TCP grafts, which was published in Quintessence International (01/2018), and the results unequivocally demonstrate the advantages of adbone®TCP. Medbone has always met my best expectations.”

European Implantology Center EIC, Portugal.

“I’ve been using adbone®TCP and adbone®BCP for 12 years which have become a reliable part of my routine clinical practice, combining ease of use with excellent biological performance. Its stability and predictability have been remarkable, providing reproducible results in challenging surgical indications such as sinus floor elevation.”

Egas Moniz School of Health and Science, Portugal.

“I have been using adbone® products for over five years, and I can confidently say that they are a benchmark in quality and reliability for bone regeneration. The clinical outcomes have been consistent and predictable, with excellent integration and patient satisfaction. The reliability of Medbone’s products allows me to work with confidence and achieve high-standard results in implantology. I highly recommend them.”

Clinical Director of D32, Portugal.

“I have been using adbone®TCP for more than ten years, consistently achieving highly satisfactory clinical results. More recently, I have also started incorporating adbone®BCP into my procedures, with equally excellent outcomes. It is easy to handle, demonstrates fast and predictable bone integration, and its quality inspires full confidence. Without a doubt, adbone® products represent a highly reliable option among synthetic solutions for bone regeneration.”

Oral Surgeon & Dental Implant Specialist, Iraq.

“adbone® products offer predictable and safe clinical performance, establishing themselves as a benchmark solution in the field of bone regeneration. During my recent visit to Medbone’s facilities, I had the opportunity to witness the technological excellence and rigorous quality control that characterize their manufacturing processes. Medbone team stands out for its professionalism, dedication, and scientific approach, qualities reflected in highly reliable and reproducible biomedical products.”

CEO of Giesse Iberica, Spain.

“I have been using Medbone biomaterials since 2017 in surgeries, specifically adbone®BCP and TCP, according to their respective indications, and I have achieved excellent clinical results, with an appropriate resorption time of the material and the formation of high-quality bone in the maxillary or mandibular region. Over this time, adbone® has proven to be a reliable and highly effective biomaterial, providing my patients with excellent clinical outcomes.”

Dentist and Implantologist, Brazil.

"As a user of adbone® for several years, I would like to highlight the versatility of the system in terms of presentation format and the anatomical areas where its application provides added value. The rapid interaction with native tissue and gradual absorption over time enhances the safety and speed of fracture and arthrodesis consolidation, which has a very positive impact on the postoperative phase of these procedures, providing greater comfort to the surgeon."

Orthopedic Surgeon – Knee / Foot & Ankle, Ponta Delgada, Portugal.

QUALITY CERTIFICATION

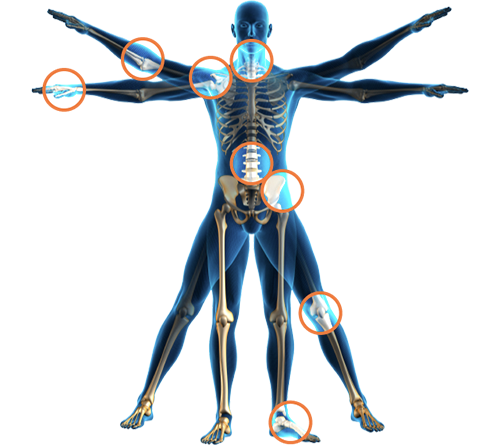

Medbone’s products are developed and made from resorbable biomaterials based on calcium phosphates.

All products are manufactured under the strictest quality controls, keeping our biomaterials at the highest scientific and quality standards, and are available in various forms: granules, blocks, cylinders, wedges and even in customized sizes and shapes.

Medical devices manufactured by Medbone have similar properties to natural bone, allowing a better quality of life for the patients.

A key feature of our products is the presence of interconnected pores or channels within the material. The channels must be large

enough (typically 0.05 mm in diameter) to enable the invasion of blood vessels and cells, hence enabling material biodegradation and bone ingrowth within the bone substitute.

To add to this great advantage, it is also important to mention that all our products, as well as the company itself, are certified by an international notified body – SGS. Medbone is certified by ISO13485, and our products are certified by the European Directive 93/42/EEC, and are currently undergoing the transition to Regulation (EU) 2017/745.

Excellent Resorption Rate

3D Structure Similar to Natural Bone

High Mechanical Resistance

Biocompatible

Several Geometries

Osteogenic

Osteoconductive

Osteoinductive

(+351) 210 938 956

Need Help? Call Us!

"After several years of using different bone graft materials, I was very curious to try a product made in Portugal. After doing so, Medbone immediately became my first choice on bone augmentation due to its presentations, properties, reliability and very high predictability in new bone formation. Its hydrophilic character is amazing and great to observe.“